Liquid cooling systems provide localized cooling superior to that of either air or gas cooling. A larger heat transfer coefficient is obtainable with liquid versus air or gas, resulting in smaller differences between component temperatures and coolant supply temperatures. The smaller temperature difference allows components to operate at lower temperatures. This improves component reliability and reduces maintenance costs. The higher heat transfer coefficients of liquid cooling systems permit larger power densities to be adequately cooled. Also, liquid cools low power density equipment more efficiently than air-cooling. Disadvantages of liquid cooling systems also should be analyzed for any potential application. Major areas to be considered are maintenance, potential leaks, fluid contamination, logistics, and potential fire hazard.

- Direct Liquid Cooling: Liquid may be used to remove heat directly from the heat source. This provides the minimum thermal resistance from the heat source to the liquid.

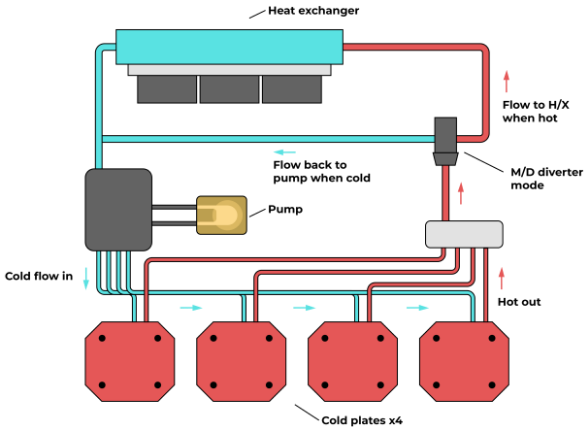

- Indirect Liquid Cooling: In this method, heat is transferred to the liquid in a liquid cooled cold plate, via an intermediate device.