Why do airplanes need Cabin Pressurization?

- Airplanes operate at altitudes where the oxygen density and the earth’s atmosphere is not appropriate and sufficient to sustain life.

- The pressurization control system keeps the airplane interior at a safe and comfortable altitude and pressure which protects the passengers and crew from the effects of rapid pressure changes and oxygen starvation called hypoxia.

- For safety of the crew and passengers as well as the integrity of the airplane a pressurization system is essential for an airplane.

- Modern airplanes utilize parts of cabin pressurization systems to maintain safe and comfortable airplane interior cabin during high altitude flights.

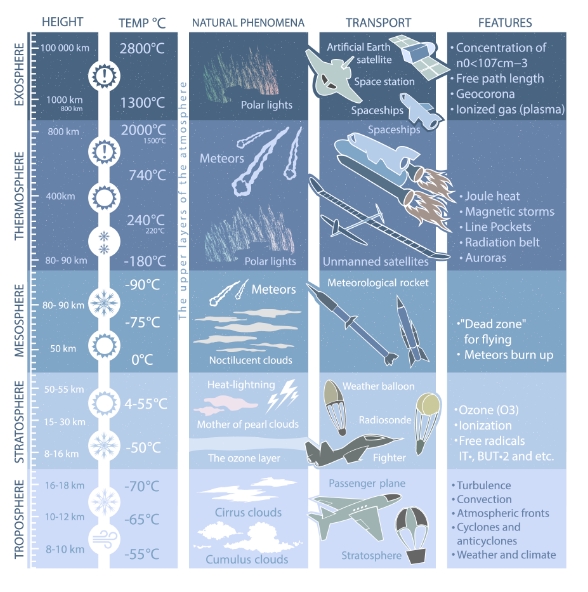

Earth’s Atmosphere

While oxygen is necessary for most life on Earth, the majority of Earth’s atmosphere is not oxygen. Earth’s atmosphere is composed of about 78 percent nitrogen, 21 percent oxygen, 0.9 percent argon, and 0.1 percent other gases. Trace amounts of carbon dioxide, methane, water vapor, and neon are some of the other gases that make up the remaining 0.1 percent.

As altitude increases, the total quantity of all the atmospheric gases reduces rapidly. However, the relative proportions of nitrogen and oxygen remain unchanged up to about 50 miles above the surface of the earth.

The atmosphere is divided into five different layers, based on temperature. A trip from the surface of Earth to outer space would result in passing through five different layers, each with very different characteristics.

Atmospheric pressure decreases with increasing altitude. Most civilian aviation takes place in the troposphere in which temperature decreases as altitude increases. The troposphere is the lowest layer of Earth’s atmosphere and is also where nearly all weather conditions take place.

The Cabin Pressurization Control System maintains the airplane interior at a safe altitude and pressure and the CabinTemperature Control System maintains the airplane interior at a comfortable temperature level in order to provide a safe environement for the crew and passengers.

Modern airplanes utilize parts of cabin pressurization systems, which are described below, to maintain safe and comfortable airplane interior cabin during high altitude flights.

Pressurization Modes

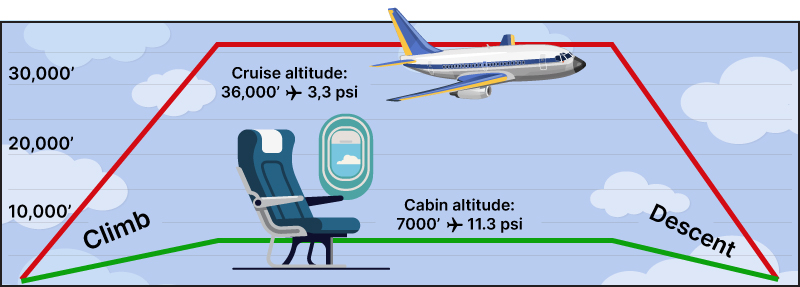

Aircraft cabin pressurization can be controlled via two different modes of operation. The first is the isobaric mode, which works to maintain cabin altitude at a single pressure despite the changing altitude of the aircraft. For example, the flight crew may select to maintain a cabin altitude of 8,000 feet (10.92 psi). In the isobaric mode, the cabin pressure is established at the 8,000 foot level and remains at this level.

The second mode of pressurization control is the constant differential mode, which controls cabin pressure to maintain a constant pressure difference between the air pressure inside the cabin and the ambient air pressure, regardless of aircraft altitude changes. The constant differential mode pressure differential is lower than the maximum differential pressure for which the airframe is designed, keeping the integrity of the pressure vessel intact.

When in isobaric mode, the pressurization system maintains the cabin altitude selected by the crew. This is the condition for normal operations. But when the aircraft climbs beyond a certain altitude, maintaining the selected cabin altitude may result in a differential pressure above that for which the airframe was designed. In this case, the mode of pressurization automatically switches from isobaric to constant differential mode. This occurs before the cabin’s max differential pressure limit is reached. A constant differential pressure is then maintained, regardless of the selected cabin altitude.

In addition to the modes of operation described above, the rate of change of the cabin pressure, also known as the cabin rate of climb or descent, is also controlled. This can be done automatically or manually by the flight crew. Typical rates of change for cabin pressure are 300 to 500 fpm. Also, note that modes of pressurization may also refer to automatic versus standby versus manual operation of the pressurization system.

Cabin Pressure Control Principles

Aircraft cabin pressure control systems can be categorized as either fixed or variable isobaric systems. These terms relate to the basic purpose of cabin pressure control, which is to regulate cabin pressure to a constant altitude at a comfortable level independent of aircraft flight altitude.

Fixed isobaric systems do not incorporate a means of selection of the

isobaric altitude. These systems always limit cabin altitude at the same level and the cabin is allowed to climb with the aircraft up to this level. Fixed isobaric systems are generally used on military aircraft where freedom from crew attention is imperative and comfort is a secondary consideration.

Variable isobaric systems incorporate an altitude selector permitting the crew to vary the selected isobaric cabin altitude based on the flight plan and aircraft structural safety pressure differential limitations.

The selector is mounted in a location accessible to the crew. The face panel of the

selector is provided with control knobs and indicator scales for adjustment of the isobaric altitude.

Typically, depending on the type and sophistication of the control system, a knob and scale isnprovided for limitation of cabin pressure rate of change, and for making correction for variation of the landing field barometric pressure, for outflow valve position indication and balancing control, for switching between system operating modes, for safety warning lights, etc.

The altitude selector is the instrument whereby crew inputs are relayed to the cabin pressure control system.