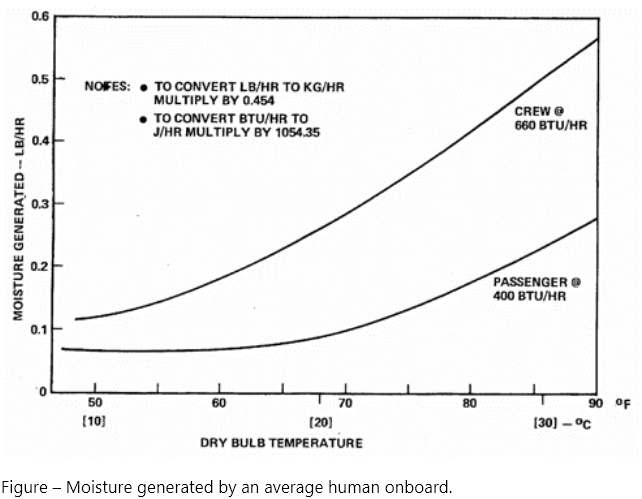

The question of passenger comfort is one of prime importance and involves not only the problems of heating, cooling and ventilation, but also humidity control both in flight at low altitudes and while on the ground. Consequently, sufficient capacity and means should be provided for removing the latent heat resulting from dehumidification, especially during ground operation in hot humid weather.

In the majority of populated ares, relative humidity is between 30% and 60%. Humidity, when combined with high temperatures causes almost immediate discomfort. In contrast to this, very low levels of humidity take a much longer period of time to be noticeable.

Both low and high humidity environments cause discomfort (excessive sweating, increased respiration, headaches, exhaustion for excess humidity and dry noses/throats, respiratory troubles and gritty eyes for low humidity) in passengers and especially in crew members, whose performance can be critical.

In addition, it is also important to exercise humidity control to prevent condensation that can damage electronic equipment and appear on windows, windshields, and on thermal and acoustical insulation. Metal parts or other high thermal conductivity materials exposed to the cabin air should be isolated from the cold skin of low flying, low speed aircraft.

Humidity in Aircraft Operating at High Altitudes

At high altitudes, the aircraft structure becomes so cold that the local temperatures can drop below the ‘dew’ point.

The dew point is the temperature to which air must be cooled to become saturated with water vapor, assuming constant air pressure and water content. When cooled below the dew point, moisture capacity is reduced and airborne water vapor will condense to form liquid water known as dew.

Other Effects of Water Condensate

Flow Control is used to

- Rain in the plane: Condensate forming on parts of the air vehicle may drip on passengers and surfaces.

- Damage to ECS equipment: Corrosion, water ingested by rotating equipment leading to failures.

- Electrical short circuits.

- Window Visibility.

- Structural Condensation: Mentioned partly in the high altitude section various effects can occur

- Wet insulation blankets

- Water accumulation in Bilge

- Overboard Icing

Humidity levels and humidity measurement in air vehicles

Cabin humidity depends on moisture generation, ventilation, and the ambient humidity and is generally measured using the following metrics

Wet bulb temperature is the lowest temperature to which air can be cooled by the evaporation of water into the air at a constant pressure.

The dry-bulb temperature is the temperature of air measured by a thermometer freely exposed to the air but shielded from radiation and moisture.

Condensation inside a cabin

Condensation inside a cabin

Moisture and Contamination Removal Solutions

General ECS Solutions (Applicable to all types of ECS)

- Auxilliary Drain: Traps/Drains at low points and throughout ducting.

- Using non-metallic materials for cold air outlets and insulating metals in contact with cold air.

- Routing lines so that water accumulation is prevented

Air Cycle Systems

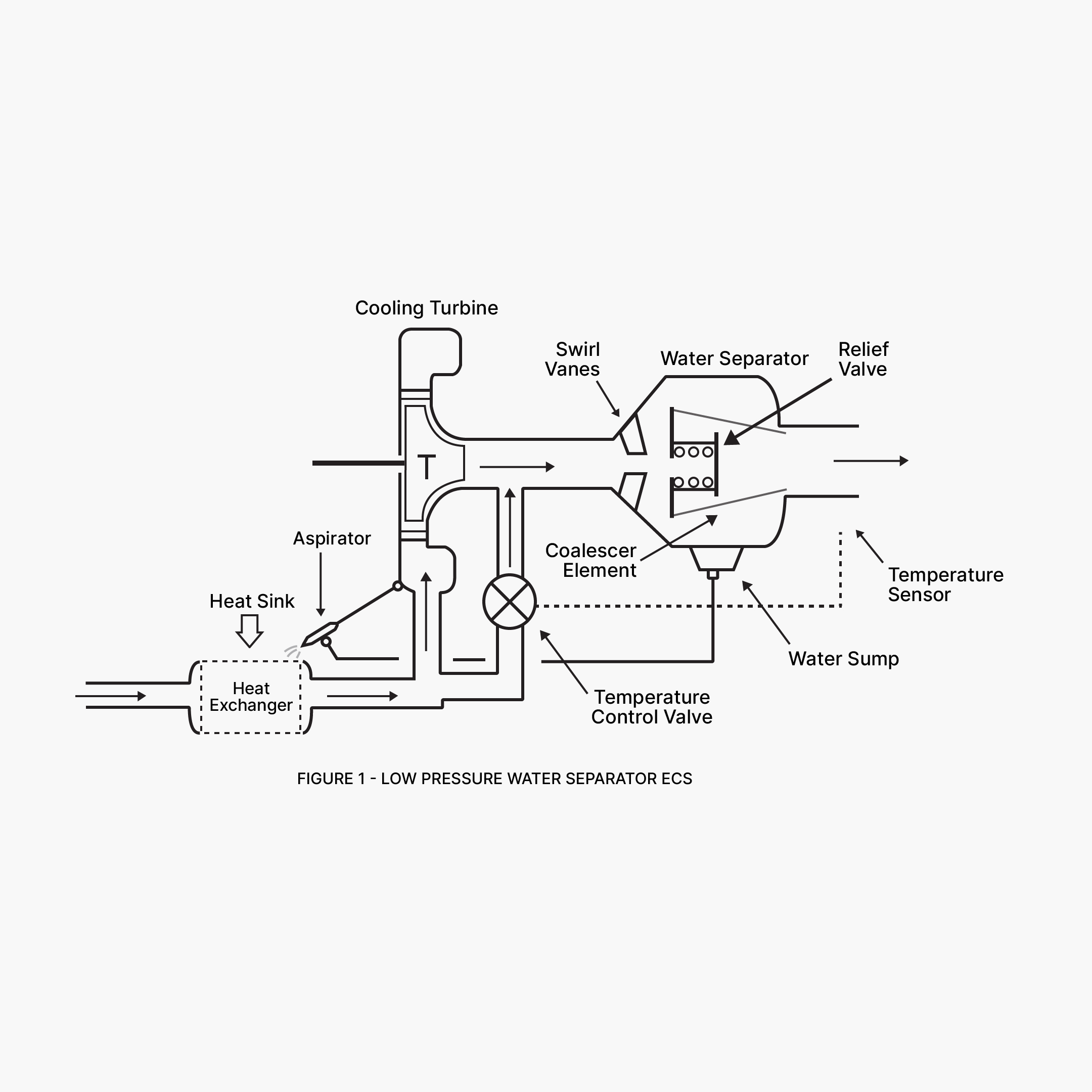

- Low Pressure Water Separators: Small water droplets are coalesced into larger droplets and collected to be collected and disposed overboard or used to be sprayed on heat exchanger core faces to increase cycle efficiencies.

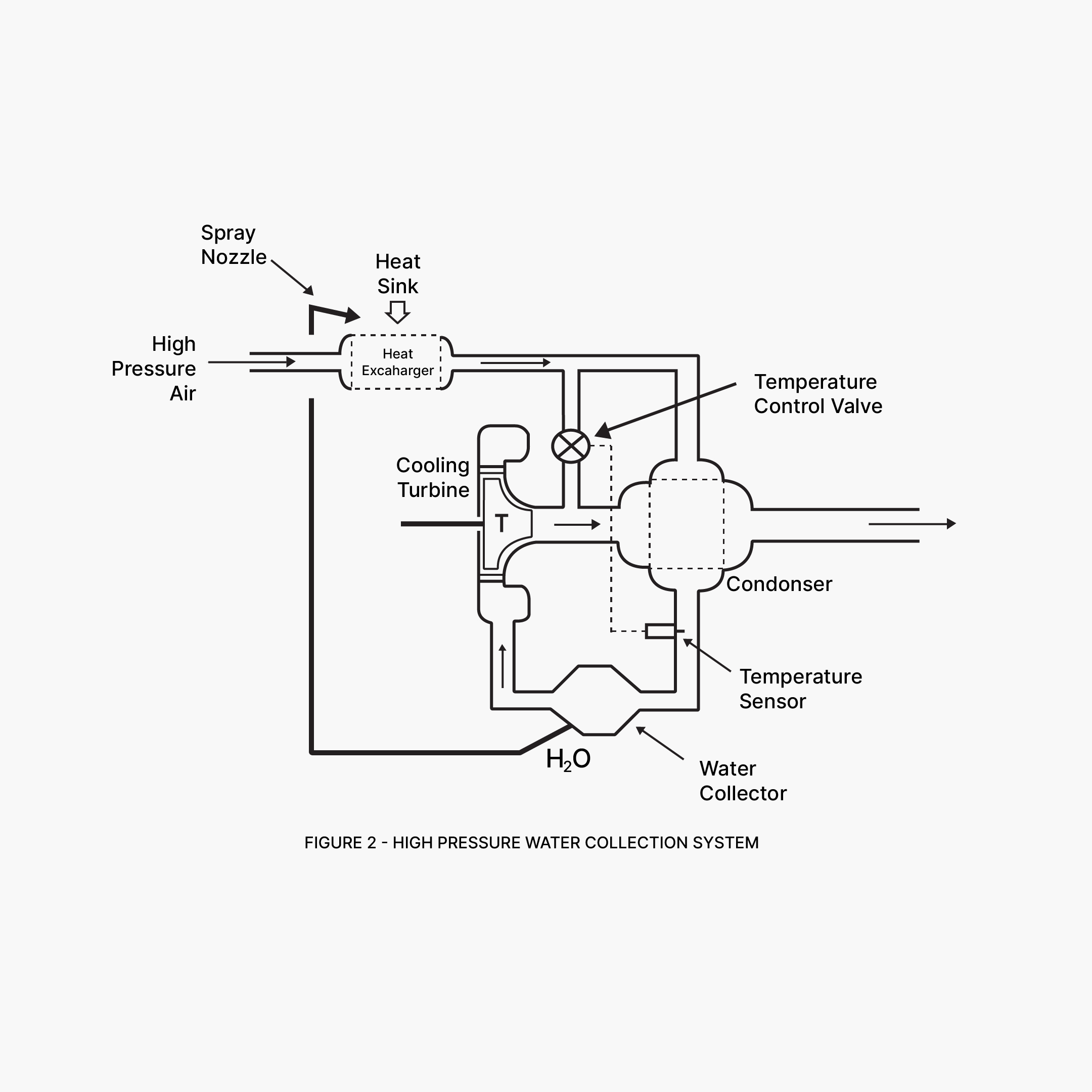

- High Pressure Water Collectors: Typically, air is cooled in a condenser, which cools inlet air. After water condenses in droplets, it can be removed using centrifugal means.

Vapor Cycle Systems

- VCS Systems have the advantage of being able to be located in the pressurized sections of air vehicles. VCS systems use their evaporators to chill the air and be simply drained.

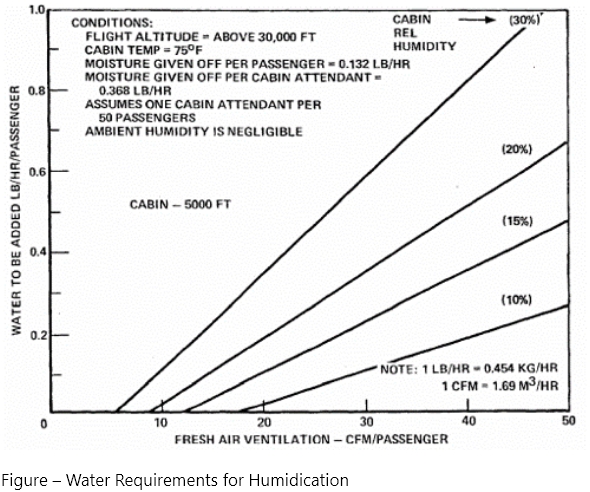

Humidification

Humidification may be required for aircraft that operate for long periods of time at high altitudes. It would be desirable to keep cabin RH between 30% and 60% however this can lead to problems due to the effects of high altitude on air vehicle temperatures. Additionally, condensation has been observed on the windscreen pillars above 30%, therefore humidity is aimed to be obtained at 20% in most air vehicle applications

Humidification can be achieved using

- Spray Atomization

- Mechanical Aerosol GeneratorsVapor Injection

- Vapor Injection

- Membrane Humidifiers

- Wicking Humidifiers